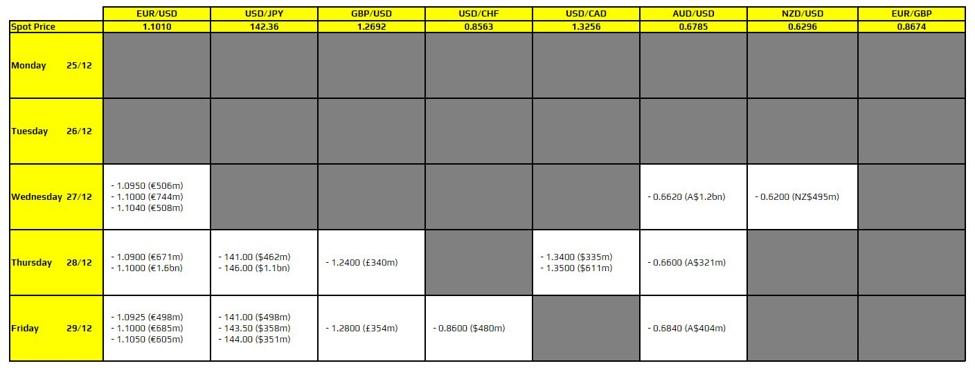

- Prior was 47.9

- Prices paid 59.0 vs 59.0 expected (58.5 prior)

- Employment 48.1 vs 44.9 prior

- Production 55.9 vs 50.7 prior

- New orders 57.1 vs 47.7 prior (revised to 47.4)

Look at that jump in new orders, which is the biggest jump in a month since 2020. That’s also the best reading since 2022.

Comments in the report don’t contain any of the optimism that we see in the headlines.

- “ ‘Hope’ has been word of the year in the Transportation Equipment

industry. Unfortunately, all the hope in the world has not materialized

into order activity in 2025 or the first half of 2026. Across the board,

buyers continue to stand on the sidelines. As we enter 2026, every

conversation revolves around hope that the second half of 2026 starts

the turnaround. It’s hard to set strategy on hope, but thanks to the

uncertainty brought about by this administration, here we are.”

[Transportation Equipment] - “Although our volume is low at the moment, the impact on the latest

tariff threats on the European Union will have a huge negative impact on

our profit for current quoted orders. We will not be able to recover

the increase tariffs in our current quotations.” [Machinery] - “Continuing softness in the market, with December orders below

average and buyers reluctant to spend despite beneficial tax policies in

the U.S. Geopolitical tensions are fueling ‘anti-American’ buyer

sentiment, and sales are being lost.” [Machinery] - “Another round of emotionally charged tariffs seems imminent,

changing the landscape once more. Movement of custom product out of

China continues, but the progress is slow with new qualifications

required for transitioned materials and assemblies.” [Computer &

Electronic Products] - “Business conditions remain uncertain. Customers are cautious.

Broad-based inflation continues. The Supreme Court tariff decision

looms.” [Computer & Electronic Products] - “Growing construction markets, data centers and energy projects, are

straining the contract labor availability. The trade tariff uncertainty

is creating volatility in the supply chain.” [Food, Beverage &

Tobacco Products] - “A new year, with new challenges. We are moving manufacturing from

China to Mexico — which will now impose tariffs on parts made in China.

This push for more of a Mexican supply chain and creates some short-term

supply management concerns.” [Chemical Products] - “Confused and uninformed tariff policies continue to plague small

companies, making long-term planning pointless. Companies are not making

capital commitments beyond 30 days.” [Fabricated Metal Products] - “Business conditions remain soft as we continue to miss sales,

orders and profits as result of increased costs from tariffs, continued

fallout from the government shutdown, and increased global uncertainty.”

[Miscellaneous Manufacturing] - “Business trends moving into 2026 feature many of the headwinds from

the third and fourth quarters of 2025. While the ‘plane’ has steadied,

there continues to be uncertainty and added costs through our global

operations. Tariff impacts on our financial performance last year cannot

be overstated, as we had a much smaller EBITDA (earnings before

interest, taxes, depreciation and amortization) than previous years.

While other inflationary pressures continue to hit the business, tariffs

and product costs played a large role. This year, we will continue our

multi-country sourcing approach to manufacture and import product from

more tariff-friendly countries outside of China. But as we know, nothing

is guaranteed with the current administration. We have trimmed costs

everywhere inside the business, including on labor and conferences, and

reduced our revenue forecast to a much more achievable mark. We’re

prepared to battle throughout the year for higher profitability.”

[Apparel, Leather & Allied Products]

This article was written by Adam Button at investinglive.com.