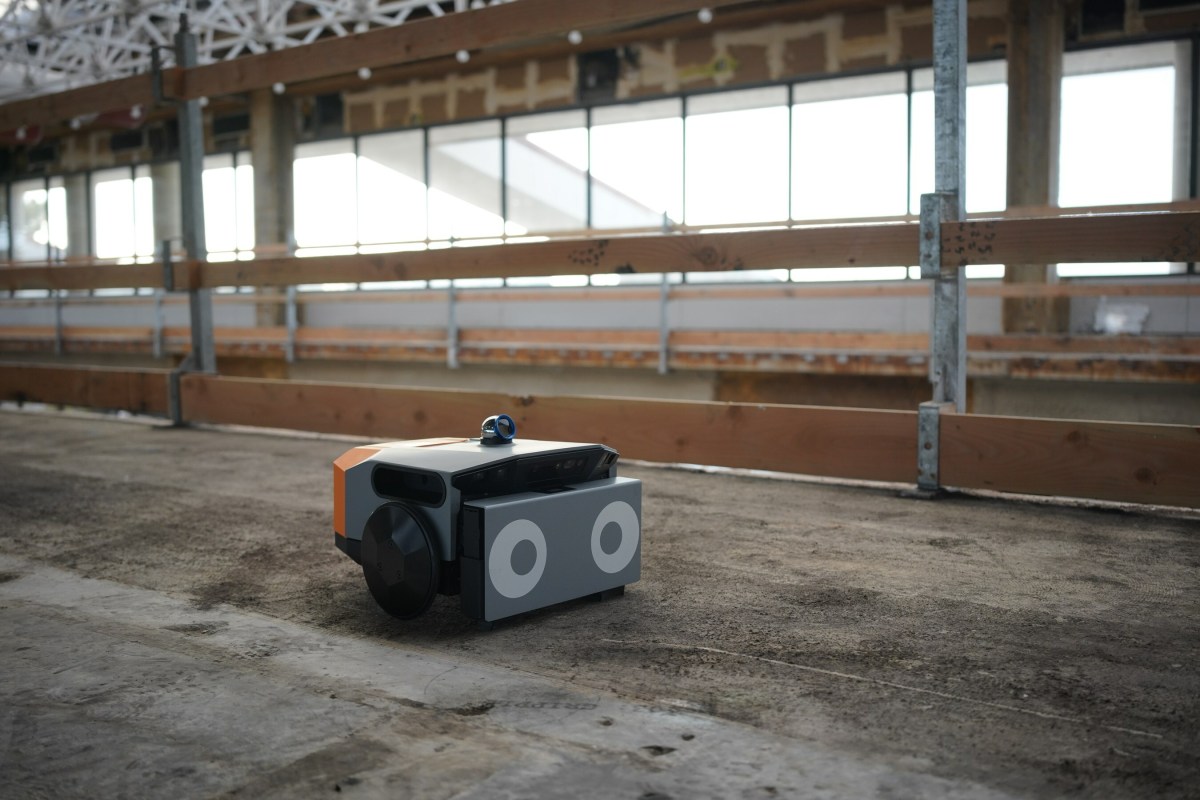

When it launched in 2019, Dusty’s FieldPrinter added a intelligent new dimension to the world of building automation. The autonomous cellular robotic introduced blueprints into the true world by drawing chalk outlines on the location’s flooring, thus eliminating a lot of the guess work in a job you actually don’t wish to guess at. The corporate says the first-gen ‘bot has to date printed greater than 91 million sq. toes.

Immediately the Bay Space-based startup is launching the sequel. As was the case with its predecessor, FieldPrinter 2 sports activities an enormous pair of pleasant eyes — personification is a surprisingly efficient strategy to combine automation into the office. The little robotic is smaller than the primary gen, thus permitting it to raised transfer round obstacles.

It now prints nearer to edges and might “shadow print” behind columns. The 23-pound robotic sports activities a wider print head and a bevy of on-board sensors for improved navigation. It can be managed through iPad.

Immediately’s information additionally marks the arrival of FieldPrint Platform, which is centered round BIM-to-field — that’s successfully bringing digital data into real-world building websites.

“Our new FieldPrint Platform supports the seamless flow of data from the design phase, to the field, and back to the trailer,” cofounder and CEO Tessa Lau notes. “More than just a robot, Dusty provides an integrated software+hardware solution that architects, designers, and field operators utilize to get unparalleled accuracy, communication, and efficiency.”

Building is at the moment shaping as much as be considered one of robotics’ greatest classes. It’s, in any case, a $2 trillion business within the U.S. alone. There are a number of features of the constructing course of which might be completely positioned for automation, particularly throughout an period of staffing scarcity. Predictably, Dusty’s progressive resolution now has some competitors, together with, most notably, HP’s SitePrint.