Some economists credit carmaker Henry Ford for jump-starting the American middle class in the 20th century when, in January 1914, he hiked factory wages to $5, more than double the average wage for an eight-hour work day.

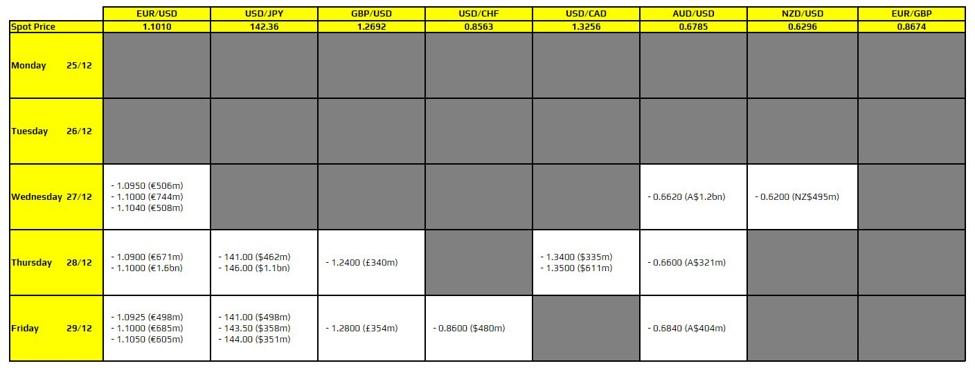

More than 100 years later, facing the reality of many employees “barely getting by,” Ford CEO Jim Farley said he took a page out of the founder’s playbook.

The carmaker’s chief executive recognized the need to make a change in his workplace when he spoke to veteran employees during union contract negotiations and learned young Ford employees were working multiple jobs and getting inadequate sleep due to low wages, Farley said in an interview with journalist and biographer Walter Isaacson at the Aspen Ideas Festival earlier this year.

“The older workers who’d been at the company said, ‘None of the young people want to work here. Jim, you pay $17 an hour, and they are so stressed,’” Farley said.

Farley learned some workers also held jobs at Amazon, where they worked for eight hours before clocking in to a seven-hour shift at Ford, sleeping for only three or four hours. At a Ford Pro Accelerate event in September, the CEO said entry-level factory workers told him they were working up to three jobs.

As a result, the company made temporary workers into full-time employees, making them eligible for higher wages, profit-sharing checks, and better health care coverage. The transition was outlined in 2019 contract negotiations with the United Auto Workers (UAW), with temporary workers able to become full-time after two years of continuous employment at Ford.

“It wasn’t easy to do,” Farley said. “It was expensive. But I think that’s the kind of changes we need to make in our country.”

Ford’s own decision to double factory wages in 1914 was not altruistic, but rather a strategy to attract a stable workforce, as well as provide a stimulus for his own workers to be able to afford Ford products.

“He said, ‘I’m doing this because I want my factory worker to buy my cars. If they make enough money, they’ll buy my own product,’” Farley said. “It’s a self-fulfilling prophecy, in a way.”

Trouble attracting Gen Z trade workers

Farley, a proponent of growing U.S. manufacturing productivity to support the essential economy, has advocated for young workers to have strong trade experiences. Earlier this month, he sounded the alarm on the shortage of manual labor jobs, saying in an episode of the Office Hours: Business Edition podcast that Ford had 5,000 open mechanic positions that have remain unfilled, despite an up-to $120,000 salary for the role.

“Our governments have to get really serious about investing in trade schools and skilled trades,” he said at the Aspen Ideas Festival. “You go to Germany, every one of our factory workers has an apprentice starting in junior high school. Every one of those jobs has a person behind it for eight years that is trained.”

Despite the U.S. seeing 3.8 million new manufacturing jobs by 2033, according to Deloitte and the Manufacturing Institute, the younger generation of workers has largely turned away from the career path. As as some ditch college degrees, Gen Z enrollment in trade schools is on the rise, but the newest generation entering the workforce is largely eschewing factory jobs, citing low wages, according to a 2023 Soter Analytics study. U.S. manufacturing jobs in the U.S. have an average $25-per-hour wage—about $51,890 per year—falling short of the average American salary of $66,600.

American carmakers like Ford may be trying to make it appealing for young workers to embark on manufacturing careers, but they are still not immune to workers’ grievances over wages. In 2023, thousands of UAW members, including 16,600 Ford employees, went on strike before reaching a contract deal in October of that year, which, beyond increasing wages, also further decreased the period of time necessary for a temp worker to become full-time.

Farley called the strike “completely unnecessary” from management’s perspective and maintained the onus of improving trade workers’ wages isn’t just on Ford.

“We’re not just going to hope it gets better,” he said. “We have the resources, and we have the know-how, after 120 years, to solve these problems, but we need more help from others.”

A version of this story originally published on Fortune.com on June 30, 2025.

More on Gen Z work trends: