Apple’s hovering inventory value over the previous twenty years has been pushed by its iconic client units. It began with the iPod and iMac. Then got here the iPhone and iPad. And extra lately, the Apple Watch and AirPods.

However there’s much more to the largest U.S. firm by market cap than simply devices. At its Silicon Valley headquarters, in a non-descript room stuffed with a pair hundred buzzing machines and a handful of engineers in lab coats, Apple is designing the customized chips that energy its hottest merchandise.

Apple first debuted homegrown semiconductors within the iPhone 4 in 2010. As of this 12 months, all new Mac computer systems are powered by Apple’s own silicon, ending the corporate’s 15-plus years of reliance on Intel.

“One of the most, if not the most, profound change at Apple, certainly in our products over the last 20 years, is how we now do so many of those technologies in-house,” stated John Ternus, who runs {hardware} engineering at Apple. “And top of the list, of course, is our silicon.”

That change has additionally opened Apple as much as a brand new set of dangers. Its most superior silicon is primarily manufactured by one vendor, Taiwan Semiconductor Manufacturing Company. In the meantime, smartphones are recovering from a deep sales slump, and rivals like Microsoft are making big leaps in artificial intelligence.

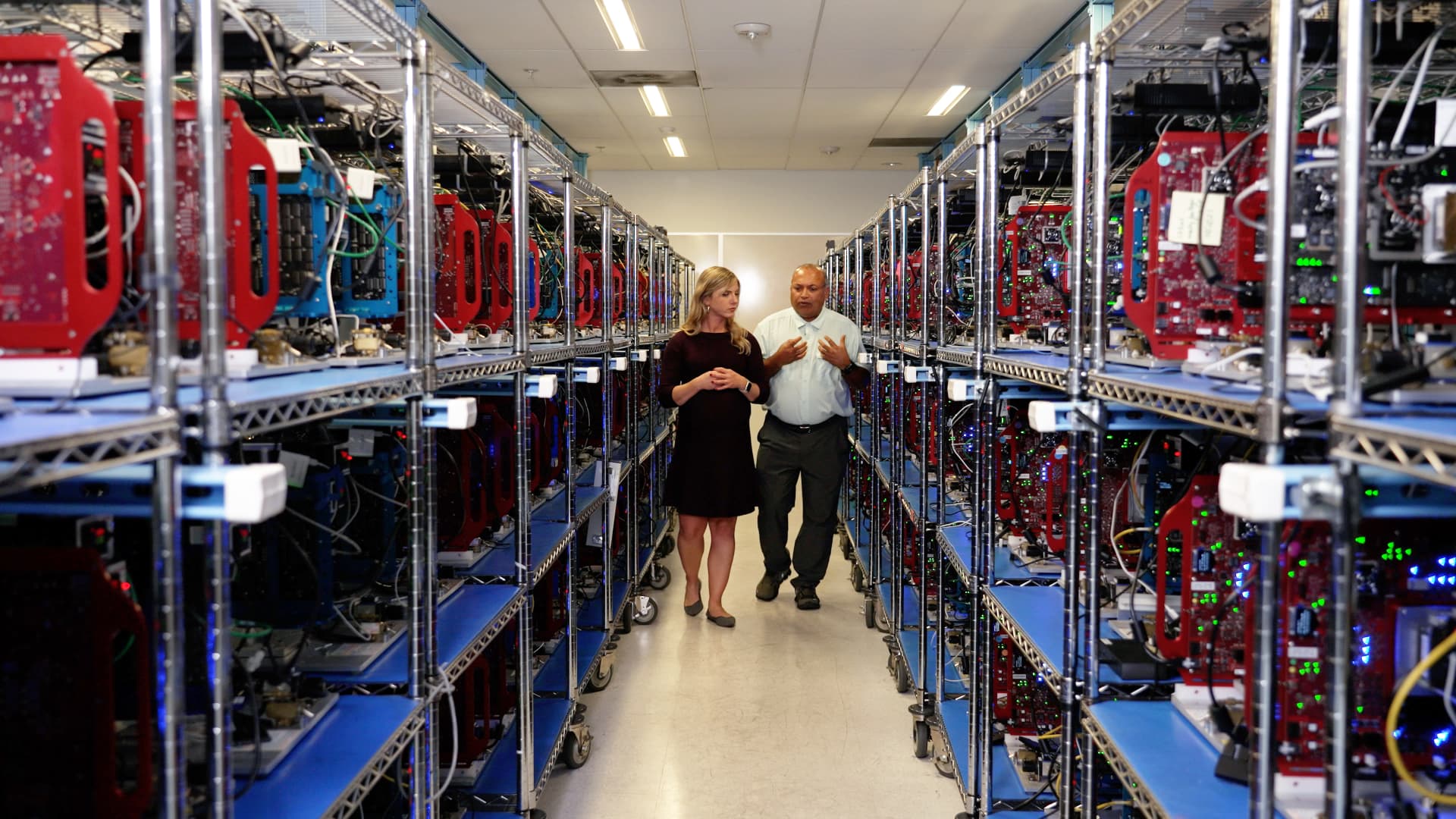

In November, CNBC visited Apple’s campus in Cupertino, California, the primary journalists allowed to movie inside one of many firm’s chip labs. We obtained a uncommon probability to speak with the pinnacle of Apple silicon, Johny Srouji, in regards to the firm’s push into the advanced enterprise of customized semiconductor growth, which can also be being pursued by Amazon, Google, Microsoft and Tesla.

“We have thousands of engineers,” Srouji stated. “But if you look at the portfolio of chips we do: very lean, actually. Very efficient.”

Not like conventional chipmakers, Apple will not be making silicon for different firms.

“Because we’re not really selling chips outside, we focus on the product,” Srouji stated. “That gives us freedom to optimize, and the scalable architecture lets us reuse pieces between different products.”

Apple’s head of silicon, Johny Srouji, talks to CNBC’s Katie Tarasov at Apple headquarters in Cupertino, California, on November 14, 2023.

Andrew Evers

Powering iPhones since 2010

Srouji got here to Apple in 2008 to steer a small staff of 40 or 50 engineers designing customized chips for the iPhone. A month after he joined, Apple purchased P.A. Semiconductor, a 150-person startup, for $278 million.

“They’re going to start doing their own chips: that was the immediate takeaway when they bought P.A. Semi,” stated Ben Bajarin, CEO and principal analyst at Inventive Methods. With its “inherent design focus,” Bajarin stated, Apple desires “to control as much of the stack” as attainable.

Two years after the acquisition, Apple launched its first customized chip, the A4, within the iPhone 4 and authentic iPad.

“We built what we call the unified memory architecture that is scalable across products,” Srouji stated. “We built an architecture that you start with the iPhone, but then we scaled it to the iPad and then to the watch and eventually to the Mac.”

Apple’s silicon staff has grown to hundreds of engineers working throughout labs everywhere in the world, together with in Israel, Germany, Austria, the U.Okay. and Japan. Throughout the U.S., the corporate has amenities in Silicon Valley, San Diego and Austin, Texas.

The first kind of chip Apple is creating is called a system on a chip, or SoC. That brings collectively the central processing unit (CPU), graphics processing unit (GPU) and different elements, Bajarin defined, including that for Apple there’s additionally a neural processing unit (NPU) “that runs the neural engine.”

“It is the silicon and all of the blocks that go on to that silicon,” Bajarin stated.

Apple’s first SoC was the A collection, which has superior from the A4 in 2010 to the A17 Professional introduced in September of this 12 months. It is the central processor in iPhones, in addition to some iPads, Apple TVs and the HomePod. Apple’s different main SoC is the M collection, first launched in 2020, which now powers all new Macs and extra superior iPads. That product is as much as the M3 line.

Launched in 2015, the S collection is a smaller system in bundle, or SiP, for Apple Watch. H and W chips are utilized in AirPods. U chips permit communication between Apple units. And the latest chip, the R1, is about to ship early subsequent 12 months in Apple’s Vision Pro headset. Devoted to processing enter from the gadget’s cameras, sensors and microphones, Apple says it should stream photos to the shows inside 12 milliseconds.

“We get to design the chips ahead of time,” Srouji stated. He added that his staffers work with Ternus’s staff “to exactly and precisely build chips that are going to be targeted for those products, and only for those products.”

The H2 contained in the 2nd technology AirPods Professional, as an example, permits higher noise cancellation. Inside the brand new Sequence 9 Apple Watch, the S9 permits for uncommon capabilities like double tap. In iPhones, the A11 Bionic in 2017 had the first Apple Neural Engine, a devoted a part of the SoC for performing AI duties completely on-device.

The most recent A17 Professional introduced within the iPhone 15 Professional and Professional Max in September permits main leaps in options like computational pictures and superior rendering for gaming.

“It was actually the biggest redesign in GPU architecture and Apple silicon history,” stated Kaiann Drance, who leads advertising and marketing for the iPhone. “We have hardware accelerated ray tracing for the first time. And we have mesh shading acceleration, which allows game developers to create some really stunning visual effects.”

That is led to the event of iPhone-native variations from Ubisoft‘s Murderer’s Creed Mirage, The Division Resurgence and Capcom‘s Resident Evil 4.

Apple says the A17 Professional is the primary 3-nanometer chip to ship at excessive quantity.

“The reason we use 3-nanometer is it gives us the ability to pack more transistors in a given dimension. That is important for the product and much better power efficiency,” Srouji stated. “Even though we’re not a chip company, we are leading the industry for a reason.”

Apple’s first 3-nanometer chip, the A17 Professional, permits ray tracing and different superior graphics rendering for improved gaming on the iPhone 15 Professional and Professional Max, proven right here in Cupertino, California, on September 12, 2023.

Katie Tarasov

Changing Intel in Macs

Apple’s leap to 3-nanometer continued with the M3 chips for Mac computer systems, introduced in October. Apple says the M3 permits options like 22-hour battery life and, much like the A17 Professional, boosted graphics efficiency.

“It’s early days,” stated Ternus, who’s been at Apple for 22 years. “We have a lot of work to do, but I think there’s so many Macs now, pretty much all Macs are capable of running Triple-A titles, which is not what it was like five years ago.”

Ternus stated that when he began, “the way we tended to make products is we were using technologies from other companies, and we were effectively building the product around that.” Regardless of a deal with lovely design, “they were constrained by what was available,” he stated.

In a significant shift for the semiconductor business, Apple turned away from utilizing Intel’s PC processors in 2020, switching to its personal M1 chip contained in the MacBook Air and different Macs.

“It was almost like the laws of physics had changed,” Ternus stated. “All of a sudden we could build a MacBook Air that’s incredibly thin and light, has no fan, 18 hours of battery life, and outperformed the MacBook Pro that we had just been shipping.”

He stated the latest MacBook Professional with Apple’s most superior chip, the M3 Max, “is 11 times faster than the fastest Intel MacBook Pro we were making. And we were shipping that just two years ago.”

Intel processors are based mostly on x86 structure, the standard selection for PC makers, with a whole lot of software program developed for it. Apple bases its processors on rival Arm structure, recognized for utilizing much less energy and serving to laptop computer batteries last more.

Apple’s M1 in 2020 was a proving level for Arm-based processors in high-end computer systems, with different huge names like Qualcomm — and reportedly AMD and Nvidia — additionally creating Arm-based PC processors. In September, Apple extended its deal with Arm by way of a minimum of 2040.

When its first customized chip got here out 13 years in the past, Apple was uncommon as a non-chip firm attempting to make it within the cutthroat, cost-prohibitive semiconductor market. Since then, Amazon, Google, Microsoft and Tesla have tried their hand at customized chips.

“Apple was sort of the trailblazer,” stated Stacy Rasgon, managing director and senior analyst at Bernstein Analysis. “They sort of showed that if you do this, you can have a stab at differentiating your products.”

Apple’s senior director of {hardware} validation Godfrey D’Souza reveals off an M3 SoC in an Apple chip lab in Cupertino, California, on November 14, 2023.

Sydney Boyo

‘Modems are exhausting’

Apple is not but making each piece of silicon in its units. Modems, for instance, are one huge element the corporate has but to overcome by itself.

“The processors have been remarkably good. Where they’ve struggled is on the modem side, is on the radio side in the phones,” Rasgon stated. “Modems are hard.”

Apple depends on Qualcomm for its modems, though in 2019, the 2 firms settled a two-year legal battle over mental property. Quickly after, Apple bought the majority of Intel’s 5G modem business for $1 billion, in a possible transfer to develop its personal mobile modem. That hasn’t occurred but, and in September, Apple signed on with Qualcomm to supply its modems through 2026.

“Qualcomm still makes the best modems in the world,” Bajarin stated. “Until Apple can do as good of a job, I have a hard time seeing them fully jump to that.”

Apple’s Srouji stated he could not touch upon “future technologies and products” however stated “we care about cellular, and we have teams enabling that.”

Apple can also be reportedly working on its personal Wi-Fi and Bluetooth chip. For now, it has a fresh multibillion-dollar deal with Broadcom for wi-fi elements. Apple depends on third events like Samsung and Micron for reminiscence.

“Our aspiration is the product,” Srouji stated, when requested if Apple will attempt to design each a part of its chips. “We want to build the best products on the planet. As a technology team, which also includes the chips in this case, we want to build the best technology that would enable that vision.”

To ship on that goal, Apple will “buy off the shelf” if it means the staff can focus “on what really, really matters,” Srouji stated.

No matter how a lot silicon Apple finally designs, it nonetheless must manufacture its chips externally. That requires huge fabrication vegetation owned by foundry firms like TSMC.

Greater than 90% of the world’s superior chips are made by TSMC in Taiwan, which leaves Apple and the remainder of the business weak to the China threat of invasion.

“There is obviously a lot of tension around, like, what would plan B be if that happened?” Bajarin stated. “There isn’t another good option. You would hope that Samsung is also competitive and Intel wants to be there. But again, we’re not right now. It’s really all at TSMC.”

Apple is a minimum of seeking to carry a few of that manufacturing to the U.S. It is committed to changing into the biggest buyer at TSMC’s coming fab in Arizona. And on Thursday Apple introduced will probably be the primary and largest buyer of the brand new $2 billion Amkor manufacturing and packaging facility being in-built Peoria, Arizona. Amkor will bundle Apple silicon produced at TSMC’s Arizona fab.

“We always want to have a diversified supply: Asia, Europe and the U.S., which is why I think TSMC building fabs in Arizona is great,” Srouji stated.

Discovering expertise

One other concern is the scarcity of expert chip labor within the U.S., the place superior fabs have not been constructed for many years. TSMC says its Arizona fab is now delayed to 2025 due to a scarcity of expert employees.

Whether or not or not it has to do with a scarcity of expertise, Apple has seen a slowdown within the launch of latest chips.

“Generations are taking longer because they are getting harder and harder,” Srouji stated. “And the ability to pack more and get power efficiency is also different than 10 years ago.”

Srouji reiterated his view that Apple has a bonus in that regard as a result of “I don’t need to worry about where do I send my chips, how do I target a larger customer base?”

Nonetheless, Apple’s actions underscore the competitiveness available in the market. In 2019, Apple chip architect Gerard Williams left to steer an information heart chip startup known as Nuvia, bringing some Apple engineers with him. Apple sued Williams over IP considerations, earlier than dropping the case this 12 months. Qualcomm purchased Nuvia in 2021, in a transfer to compete in Arm-based PC processors like Apple’s.

“I can’t really discuss legal matters, but we truly care about IP protection,” Srouji stated. “When certain people leave for certain reasons, that’s their choice.”

Apple has extra macro challenges in its core enterprise as a result of smartphone gross sales are just recovering from their lowest ranges in years.

Nevertheless, demand for AI workloads is resulting in a surge in orders for silicon, particularly for GPUs made by firms like Nvidia, whose inventory has jumped greater than 200% this 12 months tied to the recognition of ChatGPT and different generative AI companies.

Google has designed a tensor processing unit for AI since 2016. Amazon Net Companies has had its own AI chips for the info heart since 2018. Microsoft launched its new AI chip in November.

Srouji stated his staff at Apple has been engaged on its machine studying engines, the Apple Neural Engine, since years earlier than it was launched within the A11 Bionic chip in 2017. He additionally pointed to embedded machine studying accelerators in its CPU and “highly optimized GPU for machine learning.”

Apple’s Neural Engines energy what it calls “on-device machine learning features” like Face ID and Animojis.

In July, Bloomberg reported that Apple built its own large language model known as Ajax and a chatbot known as Apple GPT. A spokesperson declined to substantiate or deny the accuracy of the report.

Apple has additionally acquired more than two dozen AI firms since 2015.

When requested if Apple seems to be falling behind in AI, Srouji stated, “I don’t believe we are.”

Bajarin is extra skeptical.

“It’s doable on Apple’s last year chip, even more capable on this year’s chip with M3,” Bajarin stated, relating to Apple’s place in AI. “But the software has got to catch up with that, so that developers take advantage and write tomorrow’s AI software on Apple Silicon.”

He anticipates enhancements, and shortly.

“Apple had an opportunity to really get on that from day one,” Bajarin stated. “But I think everyone expects it’s coming in the coming year.”

Watch the video to study extra.