Should you assume rising leaves is simple, assume once more.

Lettuce isn’t the world’s most difficult crop, however as any farmer is aware of, there are many issues that pop up between planting and harvest. The gamut runs from pests to pathogens and rain — each too little and an excessive amount of.

To defend the tender greens from the merciless world, many growers have taken their crops indoors — sprawling greenhouses or buzzing warehouses have grow to be the brand new properties for all kinds of crops. However demons lurk indoors, too, and just lately they’ve been of the profit-and-loss selection. Extra losses than income, truly.

Indoor farming startups have been darlings of the startup world in recent times, with their tech-forward focus drawing about $3 billion value of funding from 2012–2022, in keeping with Crunchbase. But, within the final 12 months or so, funding to the sector has wilted: AppHarvest and Fifth Season have each filed for chapter; Iron Ox laid off nearly half its staff; and Bowery Farming went by means of rounds of layoffs and noticed its valuation slashed by Constancy.

With headwinds like these, it might appear to be the sector is headed for a mud bowl.

There are some inexperienced shoots, although. Hippo Harvest just lately raised a $21 million Sequence B on the again of its repurposed warehouse robots, TechCrunch has solely realized.

What’s extra, the spherical values the startup, submit cash, at $145 million, in keeping with PitchBook — a wholesome step up from its earlier $42 million valuation. The spherical was led by Commonplace Investments with participation from Congruent Ventures, Amazon Local weather Pledge Fund, Hawthorne Meals Ventures, and Vitality Impression Companions.

In some methods, Hippo Harvest is like its rivals: It’s hoping that it could actually develop meals extra effectively utilizing much less land and water. However what units it aside on this house is the truth that it’s extra of a robotic startup than an indoor farming firm.

Many indoor farming firms depend on automation. Computer systems management the whole lot from warmth and humidity to nutrient ranges within the hydroponic programs. Trays filled with ripe produce zip alongside tracks to allow them to be harvested.

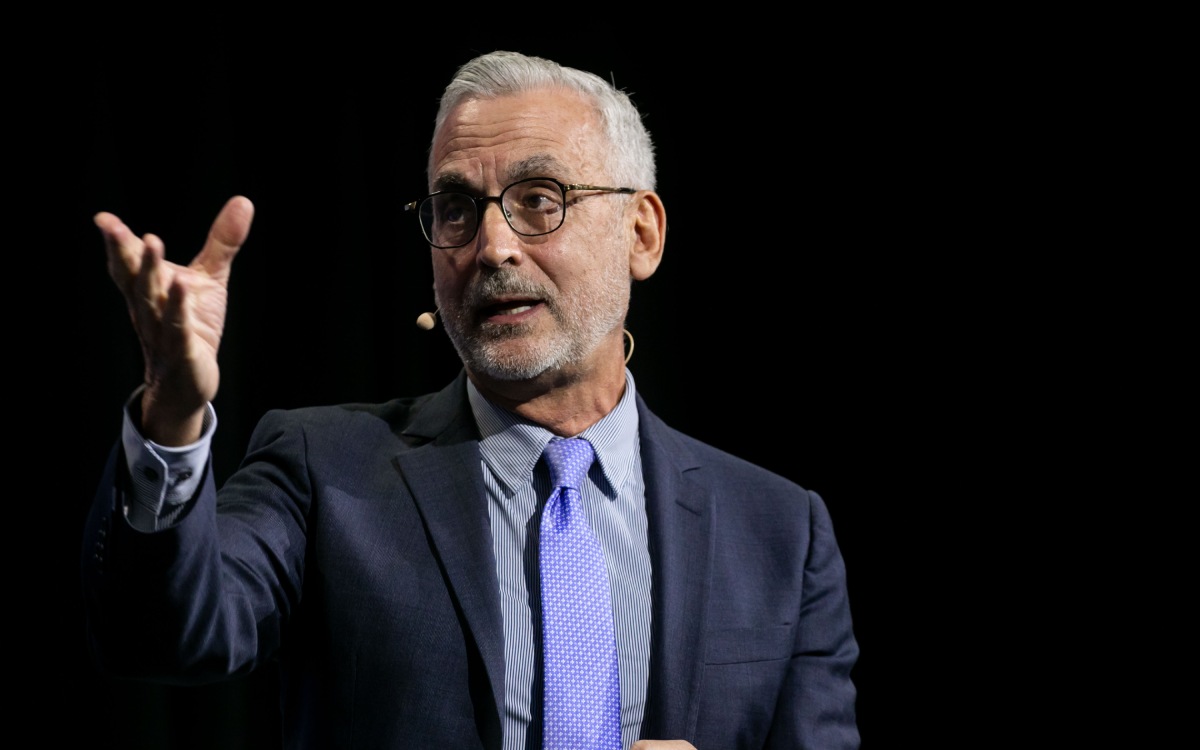

“If you go into an Amazon warehouse 15 years ago, you would see something that looks actually a lot like the greenhouses today: pneumatics, gantry systems, a lot of fixed process automation,” Hippo Harvest’s CEO Eitan Marder-Eppstein advised TechCrunch.

However Amazon’s warehouses look fully totally different now. Robots scurry about, transferring complete cabinets of merchandise from one place to a different, optimizing the format relying on demand.

These robots have grow to be so broadly used that they’ve grow to be commoditized, Marder-Eppstein mentioned. “We saw this opportunity to say, ‘Hey, what if we took those robots and turn them into tractors for our greenhouses?’” he mentioned.

It’s a choice that might form all the firm. “We went all the way back to how nurseries used to be managed. It’s truly old-school, with a person with a watering can walking around. But now we’ve got a robot that can do that.”

The robots additionally enable Hippo Harvest to run extra experiments and glean knowledge for its machine studying algorithms. When Marder-Eppstein and his co-founder Wim Meeussen began learning greenhouses, he mentioned they stored arising in opposition to one drawback: “These systems operate on these large recirculating plumbing loops,” Marder-Eppstein mentioned.

The shared loop meant they didn’t know the way a lot vitamins particular person vegetation have been receiving, they usually couldn’t maintain every plant’s microbiome separate from the others (vegetation rely closely on their microbiome to profit from the vitamins accessible to them). Such a setup would have severely restricted what number of experiments they might run.

So as a substitute of vegetation sitting in the identical shared hydroponic loop, Hippo Harvest locations them in particular person cells inside three-foot-square modules. That separation not solely allowed the greenhouse to check extra variables, it additionally inadvertently solved an issue that vexes hydroponic greenhouse operators: pathogens that swiftly unfold by means of the shared loop and kill a complete crop.

In a Hippo Harvest greenhouse, modules of vegetation sit atop a grid of posts and are separated by small aisles. The robots weave their approach underneath the flats, popping up within the aisles to ship water and vitamins, and to collect knowledge. When the vegetation are mature, they raise the flats and carry them to warehouse operators for harvest.

Hippo Harvest is sticking with greenhouses, eschewing the vertical farm in an try to avoid wasting on capital and operational bills. (Vertical farms require extra intensive lighting, heating, and air flow.)

The corporate says it could actually develop greens utilizing as much as 92% much less water, 55% much less fertilizer, and no pesticides in contrast with conventional agriculture, although it doesn’t disclose the carbon footprint of its operations. At the moment, its greenhouses are heated by pure gasoline, although Marder-Eppstein mentioned the corporate is dedicated to be internet zero by 2040.

Hippo Harvest’s produce is at the moment on the market in California by means of Amazon Contemporary and at some smaller shops all through the state, together with Mar-Val and Gus’s Group Market. The corporate plans to remain targeted on the Golden State whereas it makes use of its Sequence B funding to scale operations.

Ought to Hippo Harvest succeed, it’ll be bucking the development, little doubt to its traders’ delight. Indoor agriculture has hit a tough patch, however its potential has confirmed too attractive for some to disregard. Indoor farms promise to scale back water utilization, which is not any small feat in an period of megadroughts, and to deliver produce manufacturing nearer to properties and eating places, trimming transportation prices and emissions.

Now, all they need to do is reign in prices, and Hippo Harvest is hoping its repurposed robots will do exactly that.