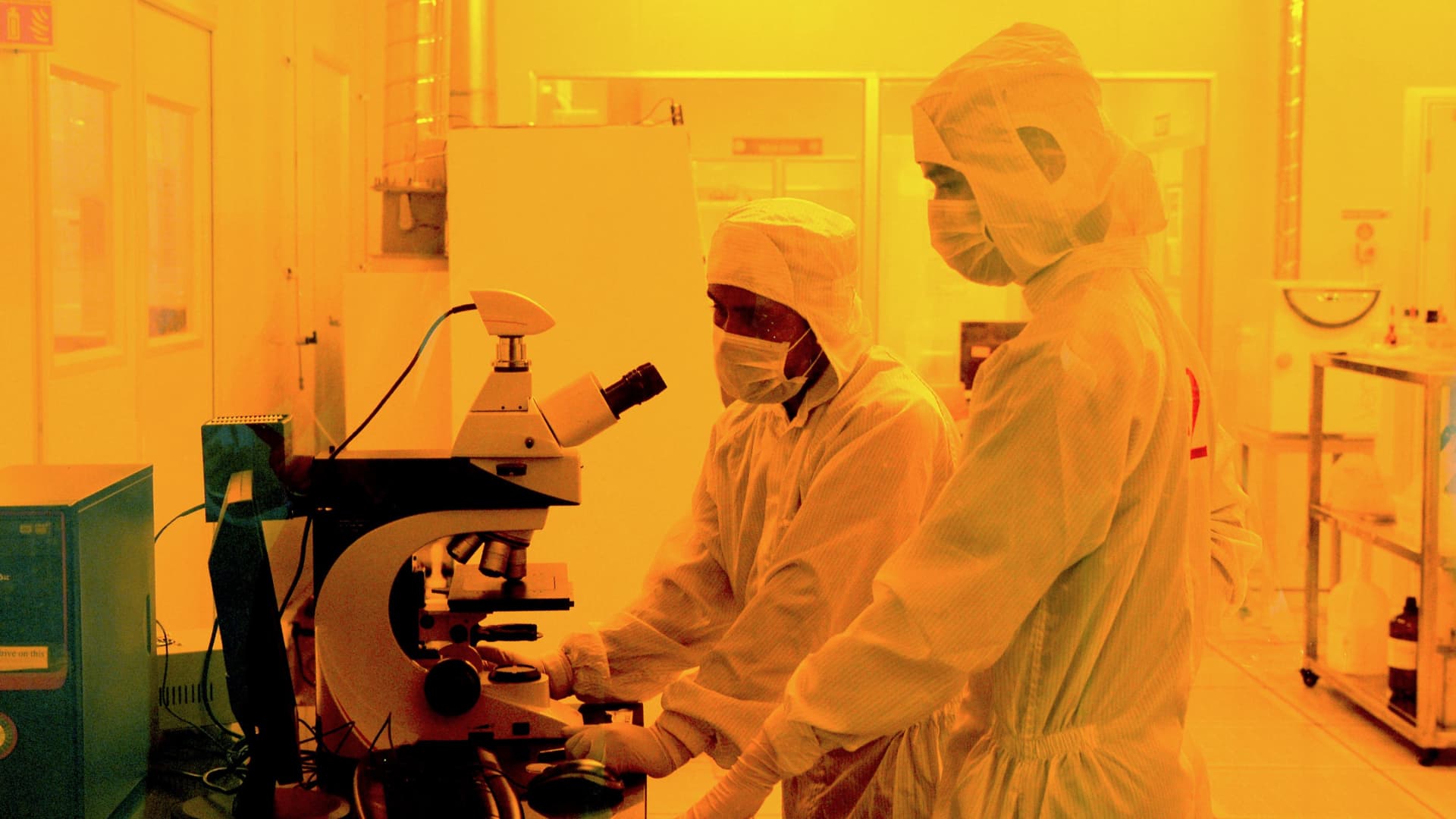

Researchers contained in the semiconductor fabrication lab on the Centre for Nano Science and Engineering, on the Indian Institute of Science, in Bangalore on June 30, 2018.

Manjunath Kiran | Afp | Getty Pictures

India has authorized building three semiconductor plants with investments of greater than $15 billion because the nation goals to change into a serious chip hub.

“India already has deep capabilities in chip design. With these units, our country will develop capabilities in chip fabrication. Advanced packaging technologies will be indigenously developed in India,” in response to a authorities assertion on Thursday.

India has ambitions to become a major chip hub on the strains of the U.S., Taiwan and South Korea, and has been courting international companies to arrange operations within the nation.

Tata Electronics will accomplice Taiwan’s Powerchip Semiconductor Manufacturing Corp to construct one of many fabrication vegetation in Dholera, Gujarat, with an funding of almost $11 billion (Rs.91,000 crore), in response to the assertion.

PSMC offers chip design and manufacturing companies within the logic and reminiscence segments. It has six semiconductor foundries in Taiwan.

The manufacturing facility will give attention to the mature 28-nanometer know-how, particularly in industries resembling vehicles, client electronics and protection. Mature know-how refers to processes concerned in making 28-nanometer or bigger chips — typically thought of legacy chips.

Tata Semiconductor Meeting and Check Pvt Ltd will arrange the second plant in Morigaon, Assam, with an funding of $3.26 billion (Rs.27,000 crore), to develop “indigenous advanced semiconductor packaging technologies including flip chip and integrated system in package technologies” for automotive, EVs and client electronics segments.

CG Energy, in partnership with Japan’s Renesas Electronics Company and Thailand’s Stars Microelectronics will arrange the third manufacturing facility in Sanand, Gujarat, specializing in chips for client, industrial, automotive and energy functions. It is going to see an funding of almost $1 billion (Rs 7,600 crore).

All three factories will begin building inside subsequent 100 days.

India in June 2023 had authorized Micron for organising a semiconductor unit in Sanand, Gujarat.

“Within a very short time, India Semiconductor Mission has achieved four big successes. With these units, the semiconductor ecosystem will get established in India,” the federal government mentioned.

These factories will immediately create 20,000 superior know-how jobs and about 60,000 oblique jobs.

World chip producers have been trying to diversify operations amid geopolitical uncertainty, which stands to learn international locations resembling India.

Taiwan Semiconductor Manufacturing Company, the world’s largest contract chip maker, most not too long ago opened a new plant in Japan because the nation is making an attempt to spice up its lagging chip-manufacturing business.