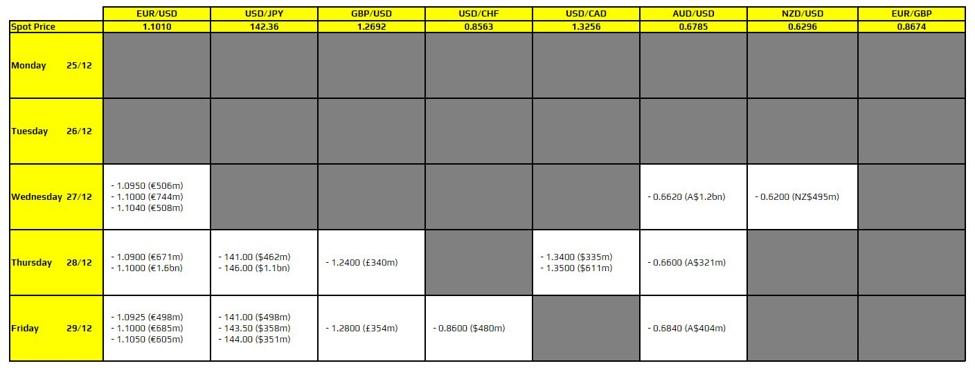

- Prior was 48.2

- Prices paid 58.5 vs 57.0 expected (58.5 prior)

- Employment 44.9 vs 44.0 prior

- New orders 47.7 vs 47.4 prior

A miserable year for US manufacturing ends with some extra disappointment. This is the lowest reading since November 2024.

ISM manufacturing index

The new orders reading was a slight improvement but still deeply in contractionary territory. The promises of tariffs aren’t paying off as companies are reluctant to invest in long-term production given the uncertainty of the legality and staying power of tariffs. Moreover, consumers are unwilling to buy expensive US-built consumer products rather than foreign imports. The prices paid component rising is ominous but it’s still well-below the 69-level from the peak of mid-2025. I suspect that falling oil prices are a big part of that but that’s something that won’t last.

On the macro side, the hangover from the post-covid spending spree continues and lower US rates don’t appear to be offering a boost yet. That could change as time goes on but a lot will need to go right to make US manufacturing work again.

Comments in the report are dire:

- “Winding up the year with mixed results. It has not been a great

year. We have had some success holding the line on costs; however, real

consumer spending is down and tariffs are ultimately to blame. I hope

for some return to free trade, which is what consumers have ‘voted for’

with their spending.” [Chemical Products] - “Trough conditions continue: depressed business activity, some

seasonal but largely impacted by customer issues due to interest rates,

tariffs, low oil commodity pricing and limited housing starts.”

[Machinery] - “Things are quieter regarding tariffs, but prices for all products

remain higher. Our costs have increased, so we have increased prices for

our customers to compensate. Margins have deteriorated, as full pass

through (of cost increases) is not possible.” [Computer & Electronic

Products] - “Things are not improving in the transportation equipment market.

Many customers are ordering for 2026, but those orders are 20 percent to

30 percent below their historical buying patterns. Some large fleets

are still completely on hold for 2026, with zero capital expenditures

money available to fleet budgets. Truck rental utilization, which is a

good benchmark for the health of the economy, is still below

historically stable levels. The general mood of the industry is that the

first half of 2026 will be another bust, and we’re now hoping things

pick up in the second half, even as the North American truck fleet

continues to age.” [Transportation Equipment] - “In the current environment, our company is struggling with customer

orders and financially overall. Our senior leaders are struggling to

focus our business and get the company on track with quality products.

In November, layoffs impacted about 9 percent of our workforce,

affecting all locations in the U.S. and Europe.” [Machinery] - “Orders continue to drop for most of our businesses. Many plants are

not running near full capacity. Make to order being utilized where

possible.” [Chemical Products] - “Order levels have continued to decline: We had a bad October, an

awful November and a dismal December. January and February don’t look

too good, as bookings are down 25 percent compared to the first two

months of 2025.” [Fabricated Metal Products] - “Morale is very low across manufacturing in general. The cost of

living is very high, and component costs are increasing with folks

citing tariffs and other price increases. It’s cold in our area of the

country, absenteeism is worse around the holidays, and sales were lower

than we expected for November. So, things look a bit bleak overall.”

[Electrical Equipment, Appliances & Components] - “Global logistics remains sensitive to geopolitical shifts. Tariffs

are influencing equipment pricing and procurement strategies.

Large-scale data center programs are absorbing and reducing availability

of resources for other sectors.” [Food, Beverage & Tobacco

Products] - “2025 revenue was down 17 percent due to tariffs. The lost revenue

has inhibited our ability to offer bonuses to employees or create and

hire for new positions.” [Miscellaneous Manufacturing]