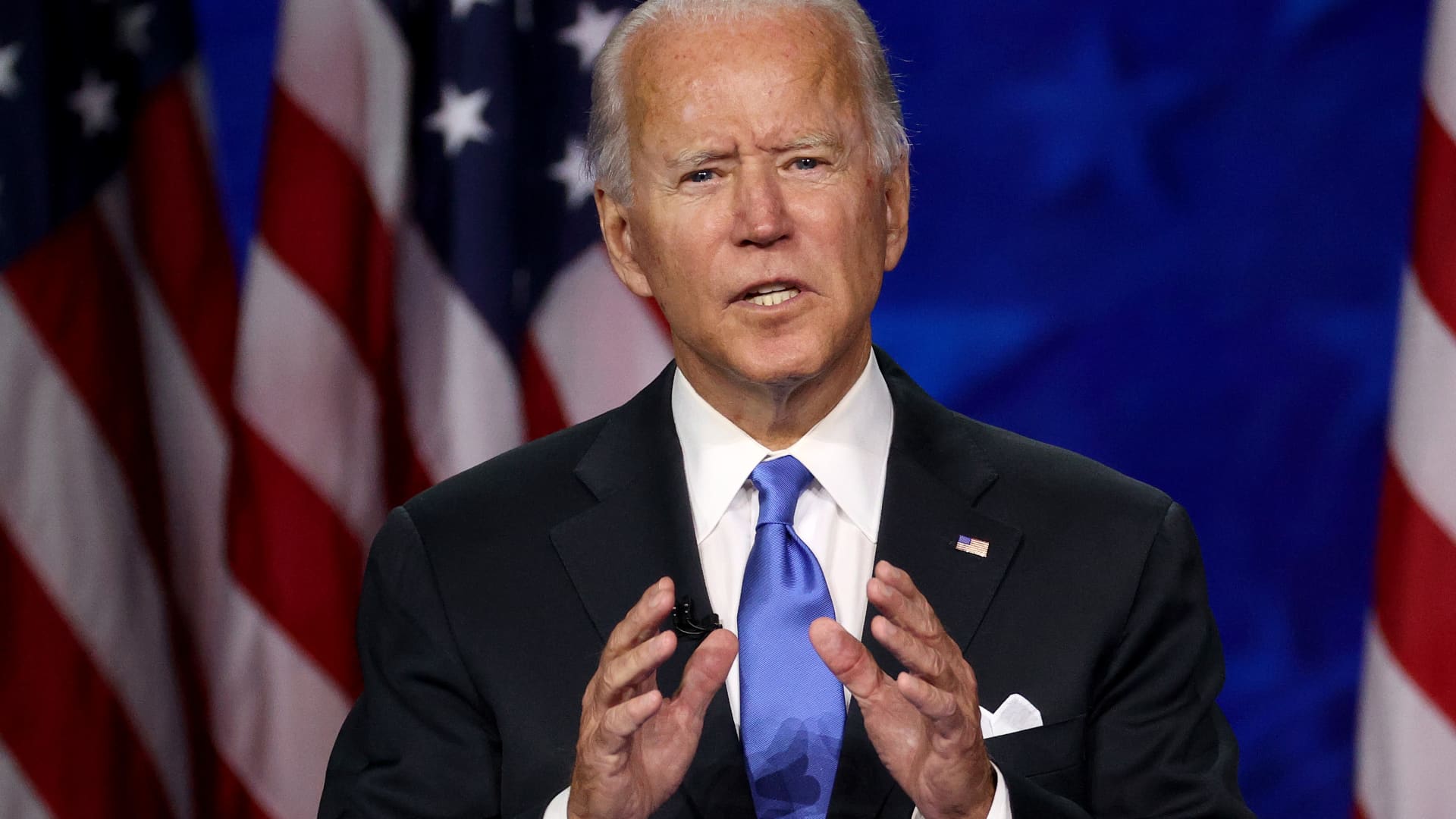

The Commerce Division announced Monday it pledged up to $6.6 billion to Taiwanese semiconductor producer TSMC, which can add a 3rd chip manufacturing facility in Arizona to the 2 within the works. The grant will go down in Washington as one of many crown jewels of the Biden administration’s initiative to deliver the provision chain for ubiquitous—and strategically important—pc chips again to america.

However in Phoenix, the place the factories are going to be constructed, TSMC faces a lingering query: the place’s the water going to return from in one of the driest cities in the country?

Semiconductor manufacturing requires water, and many it. The worldwide business consumes virtually as a lot water as New York Metropolis does, in accordance with a S&P Global Ratings report, which flagged water provide as a possible menace.

“We view water scarcity as a risk in the coming decade for the tech hardware industry, particularly the water-intensive semiconductor subsector,” S&P warned in February. “Mishandling of such a risk could hit a chipmaker’s operations and creditworthiness.”

Phoenix has been in a drought for well over a decade. In truth, Arizona put limits on some new housing developments final yr as a result of there isn’t sufficient groundwater to go round. However native officers say the town has sufficient water for TSMC, and probably much more firms, because the area emerges as a prime chip hub.

“When you’re dealing in a limited and precious resource like water, if you’re using a lot of water for one [facility], it’s an economic tradeoff,” Cynthia Campbell, Water Assets Administration Advisor for the town of Phoenix, instructed Fortune. “We do [have enough water.]”

Semiconductor fabs rely on water to wash the tiny silicon wafers that pc chips are constructed on. And as design firms equivalent to Arm and Nvidia have developed new, extra complicated cutting-edge chips to assist tech like AI, TSMC has required much more water to construct them. TSMC’s water utilization per unit has been trending up in recent times, although it’s additionally reusing water and aims to achieve a 90% recycling rate.

Nonetheless, some specialists query the precise advantages.

“90% recycling sounds really good,” mentioned Josh Lepawsky, a professor on the Memorial College of Newfoundland and Labrador and an skilled in useful resource use and waste within the electronics business. “Maybe this is obvious, but 90% means that by definition, 10% is lost, or not recycled. Every 10 days, you’ve got a 100% need for ‘new water.’”

Along with water utilization, chipmakers produce wastewater as manufacturing depends on chemical compounds which have dangerous or unknown environmental impacts. Final August, a coalition of semiconductor producers argued towards a proposed EPA regulation to ban PFAS, generally referred to as “forever chemicals,” writing that it could forestall the business from making gadgets within the U.S. and warning the “economic consequences of such a summary action by EPA are immeasurable.”

For its half, TSMC’s wastewater discharge decreased 30% between 2018 and 2022, and the corporate has dedicated to a “near zero” wastewater discharge rate for its three Arizona fabs. However once more, that pulls skepticism.

“Near zero wastewater discharge…there’s no number on that,” Lepawsky mentioned. “Is that 0.1? 1? 10?”

Phoenix’s Campbell mentioned that metropolis water officers nonetheless don’t know what TSMC’s exact discharge price shall be, however that authorities have been in shut communication with the corporate about its water use and remedy plans. TSMC and the Commerce Division didn’t instantly reply to requests for remark.

TSMC doesn’t expect all three fabs to come online until 2028, and so they’ll possible be in service for many years. Lepawsky mentioned that water circumstances might worsen in Phoenix over that timeline. However after investing $65 billion of its own cash into the fabs alongside federal grant cash, transferring to greener pastures (actually) could be a tricky capsule to swallow for TSMC.

“These are facilities where you’re expecting to be producing for 10, 20, 30 years. That’s climate change timelines,” Lepawsky mentioned. “When you’re using billions of dollars to build a new facility…at those kinds of magnitudes, you’re not just going to pick it up and move it somewhere else if water conditions deteriorate to the point where that’s an issue.”

Different Arizona officers have dismissed claims that water shortage presents a major problem for TSMC: Arizona Chamber of Commerce and Trade CEO Danny Seiden wrote in an op-ed last August that will increase in water effectivity and conservation will enable Arizona to satisfy water calls for, pointing to TSMC competitor Intel’s Chandler, Ariz. plant, which treats greater than 9 million gallons of water a day at its on-site reclamation facility.

As Arizona continues to place itself as a semiconductor manufacturing hub, Campbell mentioned Phoenix’s water provide is able to dealing with extra initiatives—so long as they line up with expectations.

“Water is not infinite. There is a limitation at some point in time, but we don’t see things hitting a wall based on the plans we’ve seen,” he predicted.